Battery Power to Test Batteries

ECS have recently completed a project with our client, to provide stored energy to a vehicle test establishment in Bedfordshire. We designed, built, programmed and commissioned the complete controls and battery integration system for this 4MW project.

This new facility is providing battery testing to most of the major car manufactures. They are carrying out endurance and consumption testing for many of the leading all electric car options both currently on the market as well as those in development.

With more than 20 batteries on test at any one time, there is a lot of power floating about. Sometimes this power is drawn from the supply grid to charge the batteries or simulate regenerated power from car braking etc and sometimes this power is delivered to the supply grid to simulate a car driving along the road.

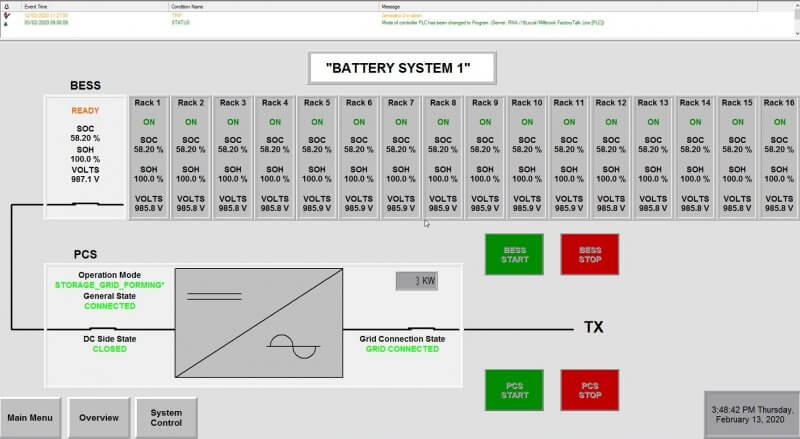

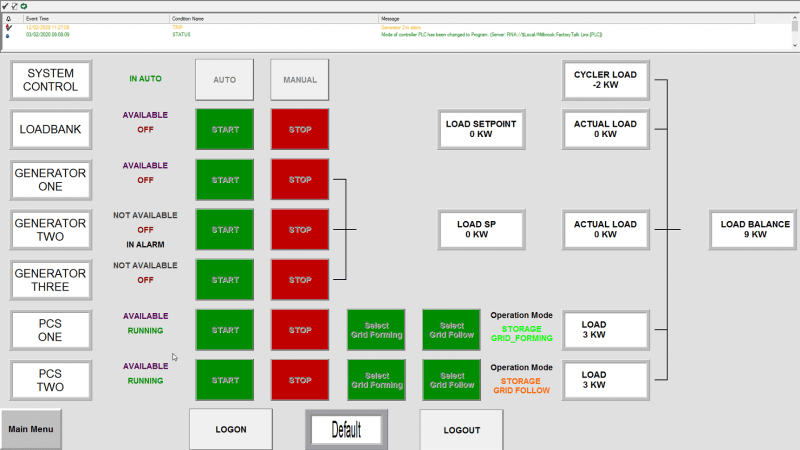

The easy option would be to connect the test lab to a suitably large mains supply. However, in this remote rural location, no such supply was available, so a completely new mini grid has been installed. It consists of generators to supply power, a loadbank to absorb power and a pair of battery storage/power converter combinations to do both supply and absorb power. All this power is distributed via a new 6,300amp LV switchboard.

The system is based on a duplex Allen Bradley ControlLogix PLC and SCADA system with custom written software. The control panels were all built and tested at our Maidstone works before being install on site. With some challenging controls algorithms, the result is a very compact, efficient and user-friendly solution.

The system is fitted with a remote access modem which means we can offer a maintenance contract that allows us monitor, adjust and fault find from anywhere in the world.

Good teamwork all!